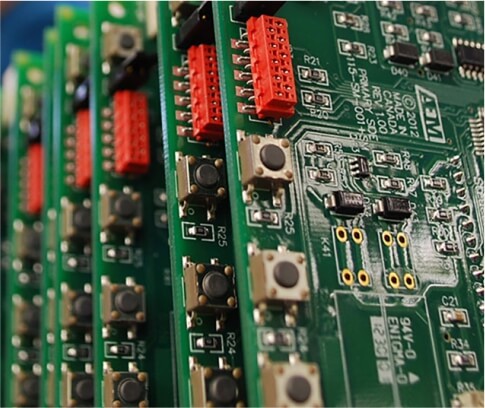

Electronic Circuit Board Repair

ERC engineers specialize in a very wide range of print circuit board repairs. We work with PCB from varied pieces of equipment including home, office, and industrial electronics. We employ serial PCB testing techniques and excellent surface-mount handling equipment to ensure the best results. We can even reverse engineer PBCs on the products that have reached EOL (End of life) status.

Typical PCB problems our engineers expertly deal with on a daily basis include:

Golden fingers

Located at the edges of a PCB, golden fingers are prone to damage. Most commonly they can get contaminated during soldering process if a technician isn’t careful enough. Fortunately, our staff at ERC can masterfully replace broken elements to make sure your PCB is working properly again.

Ball Grid Array (BGA) Pads

BGA pads are another element that can get damaged as a result of mishandling or contact with liquids. Our technicians have repaired hundreds of them, and they will swiftly fix or replace the BGA pads on your PCB.

Thru-Holes

When you have a multilayer PCB, thru-holes are a popular cost-efficient design option. If you suspect there is a problem with thru-holes on your circuit board, our engineers will inspect your PCB, and install new eyelets if necessary.

PCB Components

The components on PBC are like its vital organs – each carrying out its unique function. They might include resistors, batteries, capacitators, inductors, LEDs, diodes, switches, and transistors. Failure in components is hard to spot with the naked eye, so our engineers will make a set of tests to identify a possible problem.

Signal traces

Damage in circuit traces hinders the conduction of signals, resulting in a malfunction of the circuit board. ERC staff will fix the problem efficiently in terms of time and costs. We carry a range of trace styles to facilitate fast turnarounds for repair and replacement services.